While we wait for our boards to finish at our PCBA, we thought it would be a good idea to talk about how we're going to assemble our lenses for our review units.

The dust problem

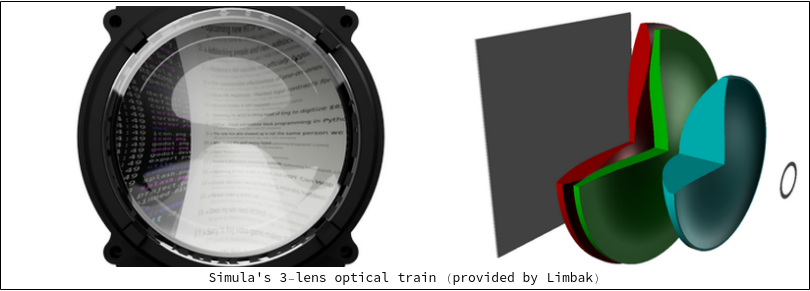

Since our headsets employ a 3-lens optical design, assembling them by hand risks getting dust trapped permanently inside them.

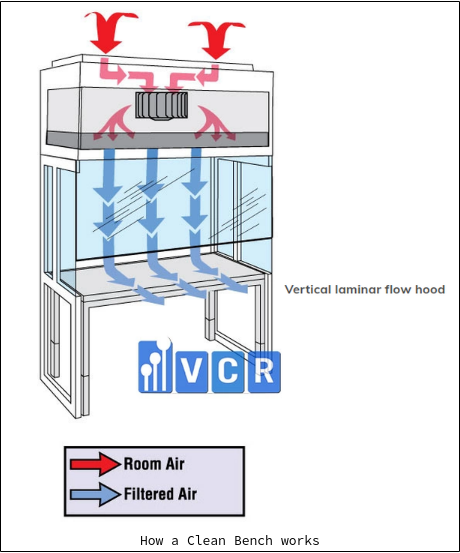

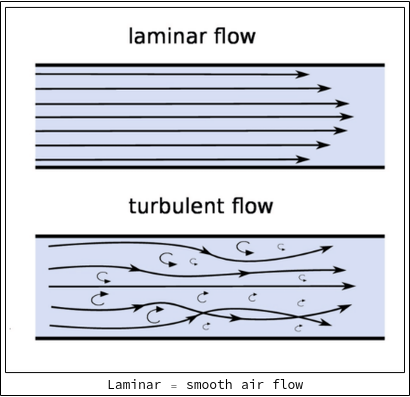

The solution is to use a laminar flow cabinet (or "clean bench") to create a dust free environment for lens assembly.

How clean benches work

A laminar flow cabinet (also called a "clean bench") is an enclosed bench designed to prevent contaimination of sensitive materials (in our case: VR lenses). Using one or more fan filter units, air is sucked smoothly through a HEPA filter (or sometimes an ULPA filter) to remove dust before it is pushed into the enclosed chamber area. Sometimes the air is recirculated back through the filter.

Faster to build than to order

Under normal circumstances, the easiest way to get a clean bench would be just to buy one; however, in our economic climate, flow benches simply aren't available with reasonable lead times (and even if they were, are ridiculously priced). So we decided the best solution – at least for quick review unit purposes – is just to build a small one ourselves (with 1218mm x 618mm dimensions):

We already have a fan-filter unit, which sits at the top of the unit:

The rest of the bench is made of a stainless steel tabletop with holes for airflow, plus an aluminum frame. Polycarbonate sheets can be retrofitted for the windows later on, if necessary.

The specific components on order:

- Various 40x40 aluminum profiles cut to size

- 40x80 Aluminum brackets for mounting the long profiles

- 40x40 brackets for mounting the short profiles

- Height adjustable levelling feet

- Laser-cut 3mm 1.4301 stainless steel sheet

Once it's complete, we'll update everyone with the finished product.